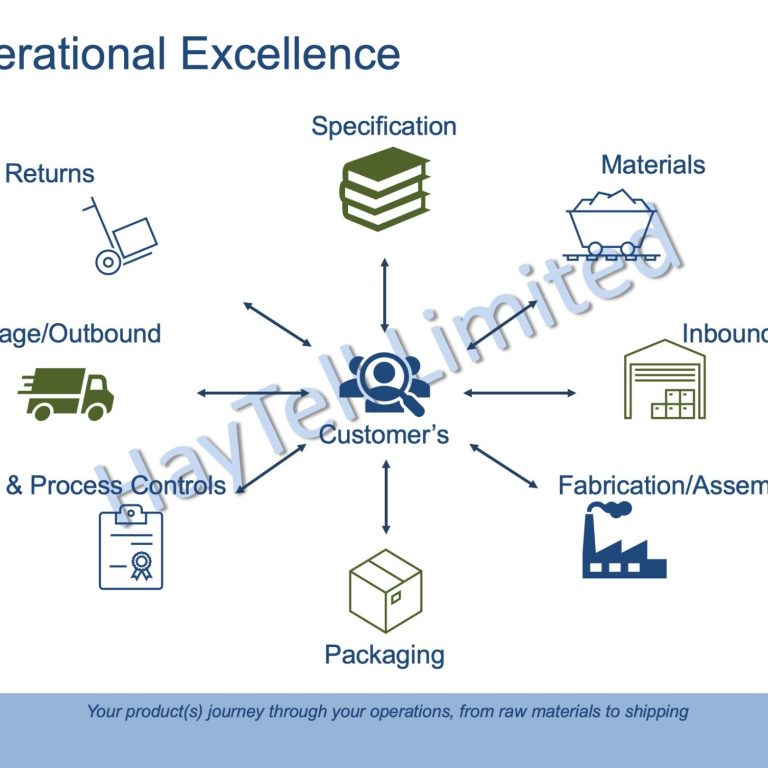

Operational Excellence

Operational Excellence is the overview and often the deep dive into the journey taken by your raw materials, sub assemblies through your production process, through packaging and onto the customer.

This for a manufacturer will often be the largest ongoing cost to your business and no matter how profitable you are, cash flow can be quickly consumed if your operation isn't lean.

The journey through your operating plant(s) can be complex, it is ripe for inefficiencies, pain points, locked in value or tied up cash. Operational Excellence emphasis on continous improvement across your operational functions, processes and capital equipment.

Our Current Operational Excellence Programmes

Your product(s) journey through your operations.

The challenge

Many moving parts, some you control 100%, some you have some control over and others you have no control over. Then add this to evolving market expectations, regulatory changes & finance.

Supply Chain

Do you have a supplier/buyer relationship, or is it a partnership agreement, is it mutually beneficial?

How do manage your supply chain’s quality of supply, service levels and terms,.

Your resources

Do you have the right layout, processes and equipment to efficiently produce. How does capacity fluctuate, do you have data at your finger tips, to make fast informed decisions and do you have sufficient cash to feed your operations.

How we can help

Global Industrial experience from: automotive, electronics, electrical, textile and plastics. There is not much we haven't experienced.

Available to SME's and larger businesses.

Operational Excellence - We have it covered!

Our vast amount of production experience, from start-ups to large blue chip corporates. Whether the challenge is in your supply chain, you plant layout, legacy processes, mature equipment or market driven change. Our goal is to provide open and clear expectations of where you can unlock value and streamline your operations.

You may find that your operations delivered outstanding performance 10 years ago, but it has matured and now is holding profitable growth back. Let's see if we can help unlock that value.

e1. Supply Chain & Materials

How did you select your supply chain and or materials specification. Who holds the power, the supplier or you?

Does your supply chain work for you, or against?

e2. Plant & Layout

Has your business grown, such that material flow now really is a problem. Have you extended and extended, but never looked back and evolved your layout. To really deliver efficiency in material flow.

e3. Processes

Has your processes evolved over time, do your processes capture potential points of failure. What happens if you produce an inferior quality product?

Does your process overcome constraints?

e4. Equipment

Is your capital equipment fully utilised, are you really sweating your assets 24/7. Is change over a hinderence to production flow and costing you considerable downtime.

e5. People

What does your workforce look like, are they an efficient cross functional team, collaboratively seeking to continously improve your operations.

e6. Warehouse & Logistics

Do you walk around your operations and see considerable amounts of (work in progress) WIP, high amounts of finished goods stock or too much raw material. Are you monitoring turns?

Are your logistics company adding value, do they integrate with your business so you can keep your customers informed of deliveries.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.